The electrolysis modernisation project at the Fos-sur-Mer plant is progressing!

21/11/24Several projects are being carried out in parallel to create what will soon be one of the most efficient electrolysis rooms in Europe!

This conversion to the best available technology (replacing the diaphragm electrolysis process with a membrane technology process) will enable Kem One to significantly reduce its environmental footprint while improving its competitiveness.

This process, which uses less electricity and natural gas, will reduce CO2 emissions into the atmosphere by 50,000 t/year, making it the largest industrial decarbonisation project currently under construction in the south of France (Provence Alpes Côte d’Azur region).

THE MAIN STAGES OF THE PROJECT: FROM SALT TO PVC

The basic and detailed studies were carried out in 2022 and 2023 in parallel with the regulatory applications. Construction began at the beginning of 2023 and we are now approaching the end of construction and the gradual transfer of the facilities to production, passing through the intermediate stages of commissioning.

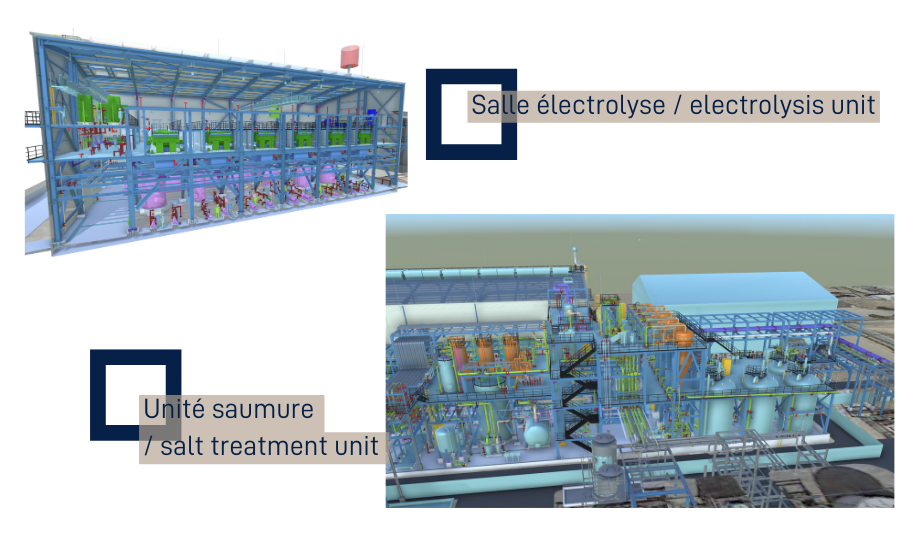

Salt and brine treatment

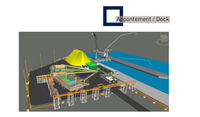

The salt unloading dock is complete: the new salt unloading crane was commissioned last April (see video on the right).

The first dissolver (equipment fed with sea salt to reconcentrate the brine) was commissioned during the summer and the second is currently being completed. The brine will be piped to the electrolysis room.

The new units for purifying the brine produced from sea salt are in the commissioning phase, with start-up scheduled for the end of the year.

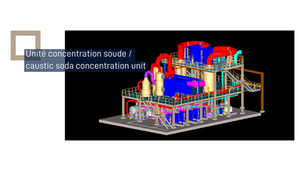

Caustic Soda: the concentration unit that will optimise steam consumption

The old diaphragm soda concentration unit will be replaced by a much more efficient unit to concentrate all the soda produced by current and future electrolysis processes. Construction of this new unit is almost complete, with some finishing work underway that will be completed by the end of the year...

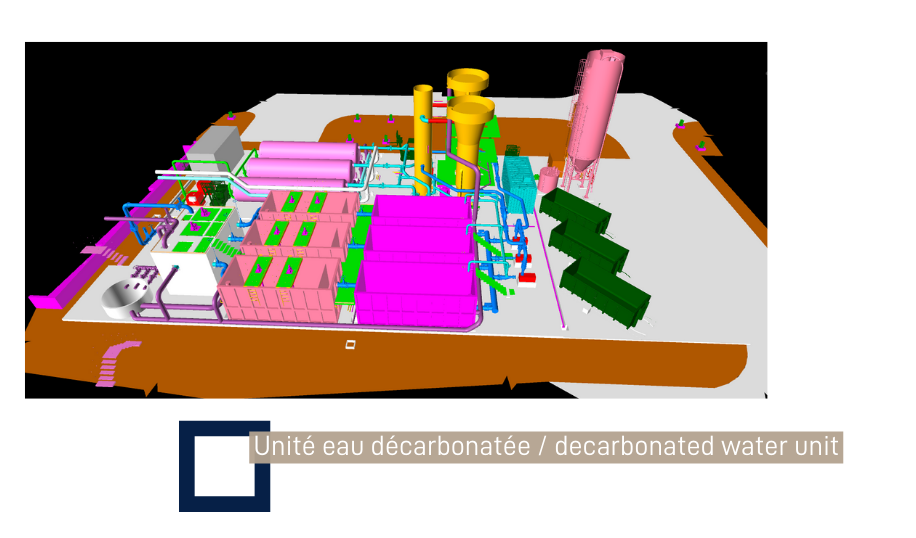

Water: purification and demineralisation

Raw water taken from the Rhône will be treated by a new unit to obtain decarbonated water, before further treatment to obtain softened or demineralised water.

Reliability work is still under way before the unit can be fully handed over to the site's manufacturing department.

The heart of the project: electrolysis

The existing membrane electrolysis unit using monopolar technology will continue to operate. It will be started up after the major shutdown of the entire Fos site, which ends in mid-November. During this shutdown, the connections (Ties-in) between the future electrolysis unit and the current units were made: more than 330 Ties-in representing the links with the utilities and process fluids.

The future bipolar membrane room is at the end of its construction phase: the site is gradually giving way to the commissioning teams, with a view to start-up in early 2025.

Would you like to find out more and find out about the highlights of the project?