E-PVC Production plant

Built in 1916 to fulfill the national defense demand for chlorine, the Saint-Auban plant is dedicated to PVC paste, used in many different applications and sectors: floor and wall coverings, synthetic leather, mastic for the automotive and construction sectors, conveyor belts, tarpaulins, toys, gloves, etc.

Dicover our E-PVC range

60 EMPLOYEES AT YOUR SERVICE

All levels of qualification are represented amongst the 60 people on the plant, as well as a wide range of professions: manufacturing operators, design and maintenance technicians, chemical engineers, administrative personnel.

To guarantee its customers the best possible result, the company prioritises the on-going skills development of all involved: the Saint-Auban plant dedicates on average 3.5% of its total payroll to on-going training.

ON-GOING QUALITY IMPROVEMENT PROCESS

Along with other KEM ONE plants, the site at Saint-Auban is ISO 9001 and ISO 14001 certified. It therefore guarantees to each one of its customers that all products will be of a consistent and impeccable quality, but will also be more environmentally-friendly and demonstrate a more sustainable approach to the use of natural resources.

TRANSPARENCY INSPIRING TRUST

The same spirit of openness and transparency also guides the community policy implemented by KEM ONE on all of their sites.

The Saint-Auban plant maintains regular communication with the surrounding communities. Plant visits, meetings with local residents and groups, participation in professional exhibitions, organising events in partnership with educational groups. Many opportunities to promote better reciprocal knowledge and create sustainable trust.

SAFETY & PROTECTION OF THE ENVIRONMENT AS A TOP PRIORITY

The safety of people and equipment is constantly monitored. Like in all KEM ONE’s plants, the management system is externally audited according to SIES standards (International System for Safety Assessment). Its activities are also governed by a Technological Risk Prevention Plan (PPRT), an Internal Operations Plan (POI) and an Individual Intervention Plan (PPI). Trained first aid representatives and ten safety officials are permanently on site.

Staff’s knowledge and practical skills are regularly updated. Safety exercises are regularly organised, either internally or in conjunction with the relevant public emergency organisations and services.

The Saint-Auban plant constantly monitors ways to minimise the impact of its activities on the environment. It has carried out significant investments in order to constantly improve in this field. It is equipped with a biological station for treating organic matter, (to processe its aqueous waste and also the area’s domestic waste), a physicochemical station to remove suspended matter and a heavy metal treatment station.

Safety and the environment are managed with complete transparency. The site regularly issues communications on these themes and is committed to announcing any significant event occurring on the premises as quickly as possible. In the event of an incident, notification is rapidly sent to neighbouring areas, to the relevant authorities, to the media and to the local residents.

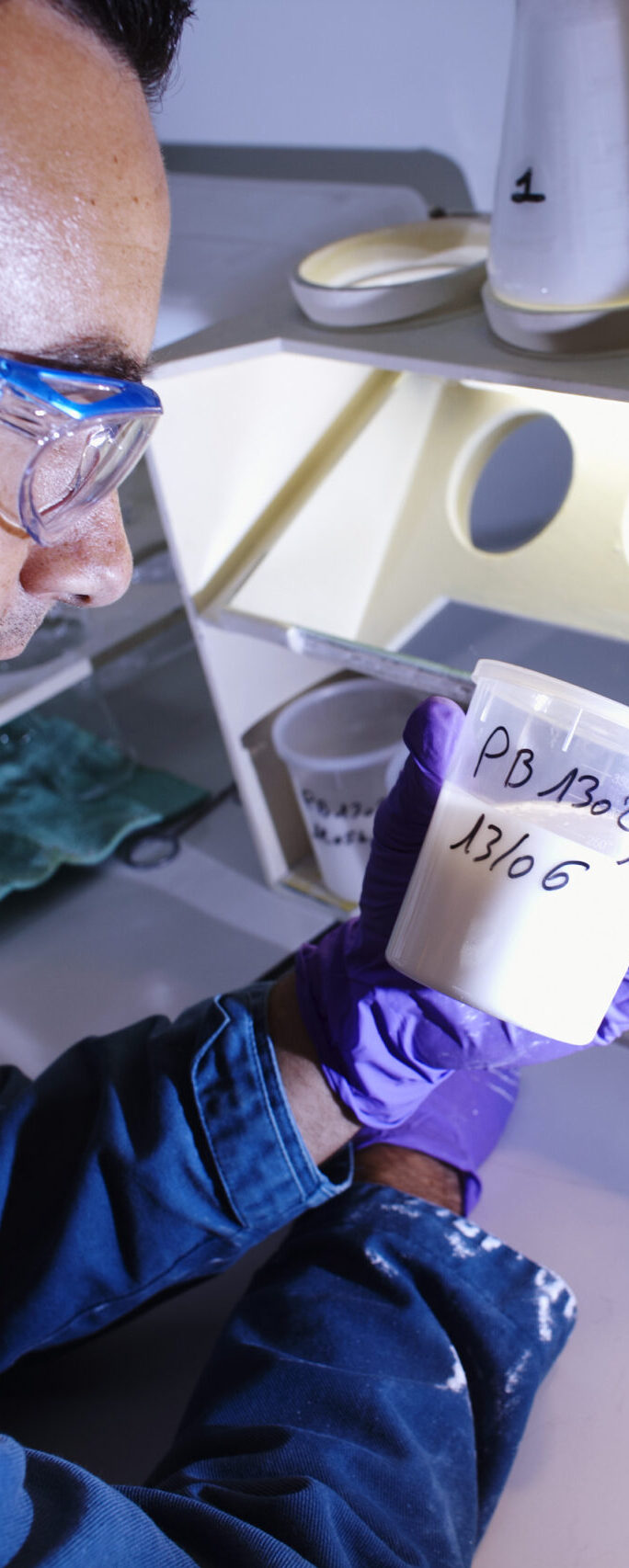

r&d center

Saint-Auban houses our R&D center, with 17 people are dedicated to:

QUALITY CONTROL

The control of semi-products ans resins Lacovyl, quality ans quality consistency being out top priority

TECHNICAL ASSISTANCE

The technical assistance to our customers and the development of customer processes

DEVELOPMENT

the development of new resins and the tests of ongoing developments (pilot resins, industrial trials).

contacts

KEM ONE – Usine de Saint Auban

Château-Arnoux

04600 Saint-Auban, France

Tel: +33 (0)4 92 33 75 00

Fax: +33 (0)4 42 33 78 17